Muchigadzirwa chekugadzira mold, chikamu chekugadzira chemuumbi chinowanzoda kucheneswa pamusoro.Kubata tekinoroji yekupolisha kunogona kuvandudza mhando uye hupenyu hwesevhisi ye mold uye nekudaro kunatsiridza kunaka kwechigadzirwa.Ichi chinyorwa chichasuma iyo yekushanda musimboti uye maitiro ekugadzira mold polishing.

1. Mold polishing nzira uye kushanda musimboti

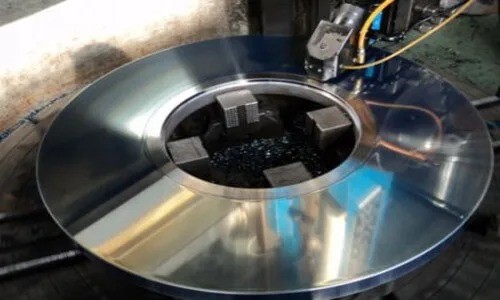

Mold polishing inowanzoshandisa matombo ematombo emafuta, mavhiri emvere dzemakwai, sandpaper, nezvimwewo, kuitira kuti pamusoro pechinhu chacho chikanganiswe nepurasitiki uye chikamu checonvex chepamusoro pechishandiso chinobviswa kuti chiwane nzvimbo yakatsetseka, iyo inowanzoitwa nemaoko. .Iyo nzira ye-super-fine grinding uye polishing inodiwa kune yepamusoro yepamusoro.Kukuya nekukwenenzvera kwepamusoro-soro kunogadzirwa nemudziyo wakakosha wekukuya.Mumvura inopenya ine abrasive, inotsikirirwa pamusoro pemuchina kuti iite high-speed rotary motion.Kupukuta kunogona kuita kushata kwepamusoro kweRa0.008μm.

2. Iyo yekukwenenzvera

(1) polish yakaoma

Fine machining, EDM, grinding, etc. inogona kukwenenzverwa neinotenderera yepasi polisher ine rotational speed ye35 000 kusvika 40 000 r/min.Kozoitawo kugayiwa kwematombo nemaoko, dombo remafuta pamwe neparafini semafuta ekuzora kana kutonhodza.Kurongeka kwekushandisa ndeye 180#→240#→320#→400#→600#→800#→1 000#.

(2) Semi-fine polishing

Semi-kupedza kunonyanya kushandisa sandpaper uye parafini.Nhamba ye sandpaper yakarongeka:

400#→600#→800#→1000#→1200#→1500#.Asi chokwadi, #1500 sandpaper inongoshandisa simbi yeforoma yakakodzera kuomesa (pamusoro pe52HRC), uye haina kukodzera simbi isati yaomeswa, nekuti inogona kukonzera kukuvadzwa pamusoro pesimbi yakaomeswa isati yaoma uye haigone kuwana inodiwa yekupukuta.

(3) Kukwenenzvera

Kukwenenzvera kunonyanya kushandisa diamond abrasive paste.Kana kukuya nevhiri rejira rinokwenenzverwa kusanganisa dhaimani poda abrasive kana abrasive paste, yakajairika kukuya order ndeye 9 μm (1 800 #) → 6 μm (3 000 #) → 3 μm (8 000 #).Iyo 9 μm diamond paste uye kukwenenzverwa jira vhiri rinogona kushandiswa kubvisa bvudzi mamaki kubva 1 200 # uye 1 50 0# sandpaper.Iko kukwenenzverwa kunobva kwaitwa nekunzwa uye nedhaimani paste muhurongwa hwe1 μm (14 000 #) → 1/2 μm (60 000 #) → 1/4 μm (100 000 #).

(4) Nzvimbo yekushanda yakanatswa

Iyo yekukwenenzvera inofanirwa kuitwa yakaparadzana munzvimbo mbiri dzekushanda, ndiko kuti, iyo yakaoma kugaya kugadzirisa nzvimbo uye yakanaka yekupurudzira nzvimbo yekugadzira yakaparadzaniswa, uye kutarisirwa kunofanira kutorwa kuchenesa jecha zvidimbu zvakasara pamusoro peiyo workpiece mune yakapfuura. process.

Kazhinji, mushure mekuporiswa kwakashata nedombo remafuta kusvika 1200# sandpaper, iyo workpiece inoda kukwenenzverwa kuti icheneswe pasina guruva, kuve nechokwadi chekuti hapana guruva remhepo rinonamira kune mold pamusoro.Kururama zvinodiwa pamusoro pe1 μm (kusanganisira 1 μm) inogona kuitwa mukamuri yakachena yekupuruzira.Kuti unyatsokwenenzverwa, inofanira kunge iri munzvimbo yakachena chose, sezvo guruva, utsi, dandruff uye madonhwe emvura anogona kurasa nzvimbo dzakakwenenzverwa.

Mushure mokunge nzira yekutsvaira yapera, nzvimbo yebasa rekushanda inofanira kuchengetedzwa kubva kuguruva.Kana iyo polishing yakamira, ese mabrasives uye mafuta ekuzora anofanirwa kubviswa zvakanyatsonaka kuti ave nechokwadi chekuti pamusoro pechishandiso chakachena, uye ipapo dhizaini yemold anti-rust coating inofanira kupfapfaidzwa pamusoro peiyo workpiece.

Nguva yekutumira: Jan-10-2021